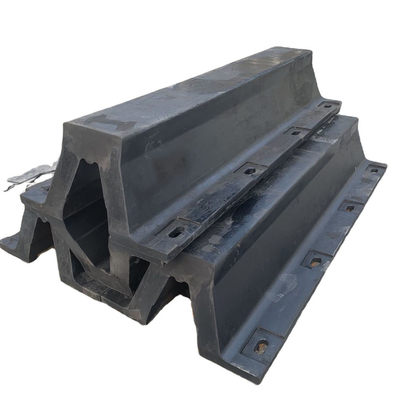

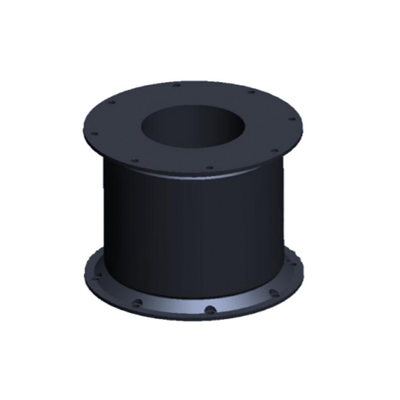

Superior Economic Efficiency and Minimized Life Cycle Cost

The pneumatic fender offers one of the most favorable ratios of energy absorption capacity to initial cost within the marine fender market. Its durable, monolithic construction, coupled with minimal ongoing maintenance demands, dramatically reduces the total cost of ownership over its extended operational lifespan. This financial prudence, encompassing both capital and operational expenditures, solidifies its status as a strategically sound long-term investment for port operators, marine contractors, and municipal authorities managing public infrastructure projects.

Unparalleled Versatility in Installation and Deployment Configurations

A paramount operational advantage is its profound adaptability. It can be seamlessly utilized as a floating fender positioned between two vessels during STS operations, suspended vertically from a quay wall face to accommodate tidal variations, or fixed horizontally to a structure as a traditional berthing bumper. This inherent flexibility empowers naval architects and marine engineers to design highly cost-effective and customized mooring solutions for non-standard, temporary, or evolving applications without incurring the significant expenses associated with bespoke, custom-designed fender units.

Reduced Weight Facilitating Simplified Handling and Installation

When compared to solid rubber fenders of equivalent energy absorption capacity, pneumatic fenders are significantly lighter due to their hollow, air-filled core. This weight reduction directly translates to lower requirements for heavy-lift equipment during installation, redeployment, and maintenance activities, thereby reducing associated labor costs, enhancing operational speed, and markedly improving worksite safety on the dock or quayside.

Consistent Performance Across a Broad Ambient Temperature Spectrum

Manufactured from a meticulously balanced and tested rubber compound, our standard-grade pneumatic fenders reliably maintain their critical elasticity, tensile strength, and energy-absorbing properties across an extensive temperature range, from -25°C to +60°C. This ensures dependable performance in the vast majority of the world's climatic zones without necessitating the procurement of special, and often costly, material variants.

Applications

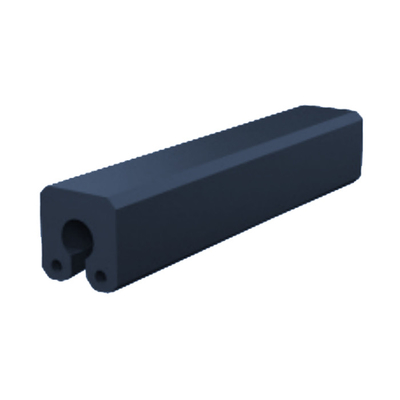

Small to Medium Sized Ports, Marinas, and Inland Waterway Terminals

This fender serves as an ideal, cost-effective primary fendering solution for ports and marinas operating under budget constraints that do not necessitate the ultra-high energy capacity of larger, more specialized, and expensive fenders. It is perfectly suited for protecting both vessel hulls and dock infrastructure in these environments, offering a robust and reliable buffer against daily berthing impacts.

Temporary Mooring, Marine Construction, and Civil Engineering Projects

Their inherent ease of deployment, retrieval, reconfiguration, and compact storage footprint establishes them as the go-to choice for temporary works. This includes applications such as bridge pier construction, large-scale dredging operations, or serving as temporary berthing facilities during comprehensive port upgrade and expansion projects.

Primary or Secondary Fendering for Tugboats, Barges, and Commercial Workboats

They are widely employed on the sides of tugs and barges to provide mutual protection for both the vessel itself and the structures or ships with which it interacts. The forgiving nature, high deflection capability, and robust construction of the pneumatic fender are exceptionally well-suited for the dynamic and often unplanned contacts characteristic of these demanding operational profiles.

Why Choose Hongruntong Marine

Unwavering Commitment to Optimal Value Engineering

We are fundamentally dedicated to providing engineered solutions that deliver maximum operational value. Our fenders are meticulously designed to meet or exceed all relevant performance standards without incorporating unnecessary premium features or over-engineering, thereby ensuring our clients pay specifically for the performance and safety they require, and not for superfluous attributes that offer no tangible benefit to their specific application.

Extensive Inventory of Standardized Products Ensuring Expedited Delivery

We proactively maintain a substantial and strategically managed inventory of standard sizes and product types. This robust inventory system enables us to offer significantly reduced lead times for common project requirements, providing a critical "off-the-shelf" availability that is indispensable for projects with aggressive timelines, emergency repair situations, or urgent replacement needs that cannot tolerate extended procurement delays.

Expert, Collaborative Guidance for Project Specific Value Engineering

Our seasoned engineering team actively collaborates with clients, consultants, and contractors from the project's inception. We specialize in practicing proactive value engineering, frequently proposing alternative fendering layouts, configurations, or product selections that successfully achieve the identical safety and performance objectives at a measurably lower overall project cost, thereby optimizing the allocated budget without compromising on quality or reliability.

Responsive, Professional Customer Service and a Streamlined Global Supply Chain

We pride ourselves on delivering a responsive, transparent, and highly professional customer service experience throughout the entire engagement lifecycle, from the initial technical inquiry to post-delivery support. Our efficient and resilient global supply chain logistics are meticulously managed to ensure that clients receive timely, accurate updates and utterly reliable delivery scheduling, rendering the entire procurement process seamless, predictable, and stress-free.

FAQ

Q1: Are pneumatic fenders suitable for permanent installation on fixed port structures?

A: Absolutely. When installed using appropriate, corrosion-resistant chains, structurally sound frames, or dedicated mooring systems as detailed in our comprehensive engineering drawings, pneumatic fenders constitute a highly reliable, durable, and cost-effective permanent fendering solution for a vast array of port, dock, and quay wall applications.

Q2: What is the recommended protocol for mitigating marine growth on the submerged sections of the fender?

A: While our proprietary rubber compound exhibits inherent resistance to marine bio-fouling, the application of specialized, rubber-compatible anti-fouling coatings to the submerged portion is recommended for enhanced and long-term protection in aquatic environments characterized by high biological activity, such as warm, nutrient-rich waters.

Q3: Are these fenders certified for use in both freshwater and seawater environments?

A: Yes, without exception. All materials utilized in the construction of our pneumatic fenders, from the inner liner and reinforcement cords to the external rubber compound, are fully resistant to degradation in both fresh and saltwater, rendering them universally suitable for inland waterways, rivers, lakes, and maritime ports worldwide.

Q4: What constitutes the minimum safe operating temperature for your standard fender compound?

A: Our standard compound is rigorously tested and certified for continuous service at temperatures as low as -25°C. For projects in permanently or seasonally colder environments, we strongly recommend and supply our specialized, premium low-temperature compound to guarantee unwavering performance integrity.

Q5: Do you provide detailed installation drawings and material specifications for integration into our structural design?

A: Yes, as a standard component of our deliverables, we provide exhaustive installation drawings, certified material specifications, and complete load-deflection data for all our fender products. This is to facilitate seamless, correct, and safe integration into your marine structure design and to ensure compliance with all project specifications.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!