manguera de caucho STS de alta presión anticorrosión flexible larga vida útil

Descripción

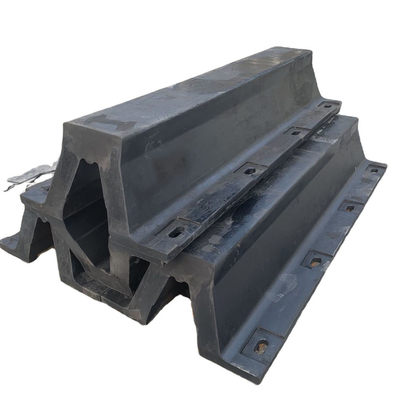

La manguera de caucho STS está diseñada para operaciones de transferencia de líquidos de barco a tierra donde la seguridad y fiabilidad son críticas.Estas mangueras proporcionan una elasticidad superior y absorción de golpes en comparación con las tuberías de transferencia rígidasSu robusto compuesto de caucho asegura durabilidad bajo duras condiciones marinas como la exposición a los rayos UV, el salpullido y el manejo abrasivo de la cubierta.

Estudio de caso: Terminal de petróleo, Singapur

Una terminal de exportación de petróleo se enfrentó a frecuentes paros debido al mantenimiento de la tubería y problemas de fugas con viejas mangueras de compuestos.Ahorro estimado de USD 250La flexibilidad superior de las mangueras también acortó los tiempos de carga de los buques en un 12%, aumentando directamente el rendimiento de la terminal.

Especificaciones

| El material |

PTFE, alambre de acero galvanizado, tejido de poliéster recubierto de PVC |

| Nombre del producto |

STS manguera |

| Tamaño |

HM-SH78 |

| Cables interiores |

Acero inoxidable 316 |

| Revestimiento |

Polyamida |

| Carcasa |

Tejidos de poliamida, películas de poliéster |

| Cables exteriores |

Acero inoxidable 316 |

| Presión de trabajo |

10 bar a 21 bar |

| Duración máxima |

40 metros |

| Muestra |

Disponible |

| Tiempo de entrega |

Normalmente de 3 a 5 días |

| Modelo |

Las dimensiones |

Presión de trabajo |

Factor de seguridad |

Radius de flexión |

Peso |

Duración |

| Compuesto |

- ¿Qué quieres decir? |

[pulgadas] |

- ¿Qué quieres? |

[psi] |

[kg] |

[m] |

| HM-SH20 |

20 |

3/4 de pulgada |

16 |

230 |

6:1 |

80 |

0.8 |

40 |

| HM-SH25 |

25 |

1 " |

16 |

230 |

6:1 |

100 |

1 |

40 |

| HM-SH32 |

32 |

11/4" de largo |

16 |

230 |

6:1 |

125 |

1.3 |

40 |

| HM-SH40 |

40 |

11/2" |

16 |

230 |

6:1 |

140 |

1.5 |

40 |

| HM-SH50 |

50 |

2 " por segundo |

16 |

230 |

6:1 |

180 |

2.5 |

40 |

| HM-SH65 |

65 |

21/2 " |

16 |

230 |

6:1 |

200 |

3.3 |

40 |

| HM-SH80 |

80 |

3" de largo |

16 |

230 |

6:1 |

260 |

4 |

40 |

| HM-SH100 |

100 |

4" de largo. |

16 |

230 |

6:1 |

380 |

6.8 |

40 |

| HM-SH125 |

125 |

5" de largo. |

16 |

230 |

6:1 |

440 |

9.2 |

40 |

| HM-SH150 |

150 |

6" de largo |

16 |

230 |

6:1 |

500 |

13.2 |

40 |

| HM-SH200 |

200 |

8" de largo |

16 |

230 |

6:1 |

750 |

18 |

40 |

| HM-SH250 |

250 |

10" de largo. |

16 |

230 |

6:1 |

900 |

26 |

25 |

| *Nota: Se pueden personalizar varios tamaños según los requisitos. |

Características

Estructura de alta elasticidad

El caucho proporciona una flexibilidad superior, absorbiendo las cargas de choque causadas por el movimiento del buque.

Ejemplo: durante las fuertes oleadas, la manguera se dobla suavemente sin torcerse, lo que garantiza una transferencia continua de líquido.

Refuerzo de múltiples capas

Diseñada con capas de refuerzo de alambre textil y de acero, la manguera puede soportar SWL hasta 21 bar de presión de trabajo.

En comparación con las mangueras estándar, el caucho reforzado mantiene su forma bajo presión de oleaje, lo que reduce los riesgos de rotura.

Compuesto de caucho anticorrosión

El revestimiento interno es resistente al aceite, a los disolventes químicos y a la entrada de agua de mar, lo que garantiza una degradación mínima incluso en las transferencias de carga agresivas.

Valor: Reduce los ciclos de reemplazo, reduciendo el costo de propiedad durante toda la vida útil en un 40% en comparación con las mangueras convencionales.

Revestimientos de seguridad mejorados

Las capas exteriores se tratan con estabilizadores UV y recubrimientos antiabrasivos, por lo que son ideales para almacenamiento al aire libre a largo plazo.

Ventajas: Mantiene su integridad incluso después de una exposición prolongada a la luz solar, a diferencia de las mangueras sin recubrimiento más baratas.

Aplicaciones

Terminal de petróleo y gas

Operación: Conecta el colector del buque con la tubería de tierra para petróleo crudo o refinado. Requiere cables de conexión a tierra para evitar la acumulación estática.

Nota de seguridad: es fundamental una inspección periódica del desgaste en los puntos de enganche.

Cisternas de productos químicos

Resistente a una amplia gama de sustancias químicas líquidas. Los operadores deben verificar la compatibilidad química con el revestimiento interno antes de transferir.

Unidades de almacenamiento flotantes (FSU)

La manguera permite el posicionamiento dinámico de los buques sin interrupción.

Bunker de emergencia

Portable y rápido para desplegar durante el reabastecimiento de combustible en alta mar.

¿Por qué elegir Hongruntong Marine?

Ingeniería del caucho probada

Décadas de experiencia en el compuesto de caucho de grado marino garantizan una resistencia química y mecánica superior validada por las normas ISO y OCIMF.

Estricto control de calidad

Todas las mangueras se someten a pruebas hidrostáticas y de vacío antes de la entrega.

Apoyo de ingeniería adaptado

Diseñamos longitudes de manguera personalizadas, diámetros y accesorios de extremo para que coincidan con las tasas de flujo operativo de cada terminal.

Red global de servicio postventa

Las mangueras de repuesto y los acoplamientos se almacenan en centros regionales, lo que garantiza un reemplazo rápido y un tiempo de inactividad mínimo para nuestros clientes.

Preguntas frecuentes

1P: ¿Cuál es la presión máxima de trabajo de su manguera STS de caucho?

R: Los modelos estándar funcionan hasta 21 bar.

2P: ¿Cómo se debe almacenar la manguera cuando no está en uso?

R: Conservar en un lugar sombreado y seco, enrollado libremente sin curvas afiladas.

3P: ¿Se puede utilizar en temperaturas bajo cero?

R: Sí, con compuestos de caucho de baja temperatura, la manguera se mantiene flexible hasta -30°C. Las versiones estándar tienen una temperatura de -20°C a +80°C.

4P: ¿Qué mantenimiento se requiere?

R: Inspeccione los acoplamientos, la abrasión de la cubierta exterior y el desgaste del revestimiento interno una vez al trimestre.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!