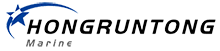

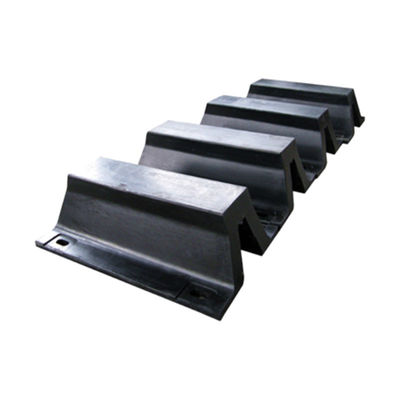

Absorción de energía optimizada con baja fuerza de reacción

El diseño curvo en forma de V transforma eficientemente la energía de impacto cinético en deformación controlada, minimizando las cargas reactivas en las estructuras del muelle. Esto asegura el atraque estable de embarcaciones de diferentes desplazamientos, reduciendo la fatiga estructural y protegiendo tanto los barcos como los activos portuarios. El defensa mantiene un rendimiento energético constante incluso después de miles de ciclos de compresión.

Compuesto de goma reforzada para una durabilidad superior

Cada defensa está fabricado con goma de primera calidad mezclada con polímeros sintéticos para una mayor resistencia al desgarro, retención de la elasticidad y protección ambiental. La formulación del compuesto proporciona una resistencia excepcional al ozono, la radiación UV, el agua de mar y el envejecimiento, lo que prolonga la vida útil incluso en atmósferas marinas tropicales o contaminadas.

Diseño compacto y fácil instalación

Los defensas de arco son ligeros y modulares, lo que permite una instalación rápida y segura en muros de muelle planos y curvos. Los pernos de anclaje estándar y las placas de acero galvanizado proporcionan una fijación fuerte, mientras que las almohadillas frontales de UHMW-PE opcionales reducen la fricción y el desgaste de la superficie. Esta estructura compacta los hace ideales para proyectos de modernización o expansión con espacio limitado.

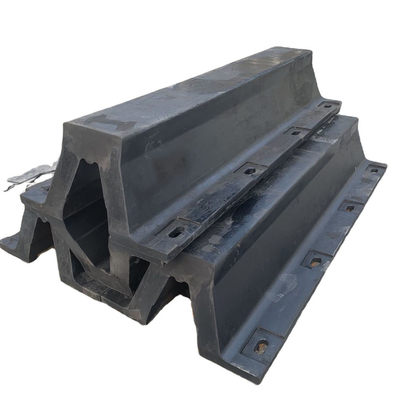

Rendimiento constante en variaciones de temperatura y mareas

La elasticidad estable de la goma asegura un rendimiento fiable en climas extremos, desde temperaturas árticas bajo cero hasta alta humedad tropical. Incluso bajo el movimiento de las mareas, el defensa mantiene una absorción de energía y una recuperación de la compresión constantes, lo que garantiza una protección a largo plazo con requisitos mínimos de mantenimiento.

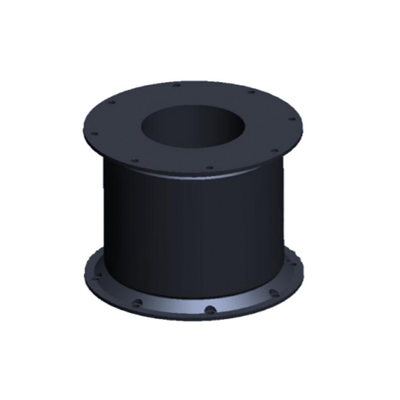

Aplicaciones

Puertos comerciales y terminales de contenedores

Proporciona una protección fiable contra impactos durante el atraque frecuente de buques de carga, graneleros y portacontenedores. La forma de arco asegura una distribución eficiente de la energía, protegiendo los muros del muelle de las tensiones repetitivas de atraque.

Puertos pesqueros y embarcaderos para embarcaciones pequeñas

Ideal para embarcaciones más pequeñas que requieren soluciones de defensa compactas, rentables y duraderas. Sus opciones de instalación flexibles lo hacen perfecto para muelles de madera o hormigón con condiciones de calado variables.

Astilleros industriales e instalaciones de apoyo en alta mar

Se utiliza para diques secos, muelles de reparación y bases de suministro donde se produce un contacto frecuente con los buques. La alta resistencia a la abrasión y el rendimiento estable del defensa lo hacen adecuado para ciclos operativos exigentes.

¿Por qué elegir Hongruntong Marine?

Estándares de ingeniería global e integridad de los materiales

Hongruntong Marine fabrica defensas de goma de arco de acuerdo con las directrices ISO 17357, PIANC e IALA. Cada defensa se somete a pruebas de compresión, verificación de la resistencia a la tracción y análisis de envejecimiento acelerado para garantizar una calidad uniforme y un rendimiento energético constante en condiciones marinas reales.

Fabricación avanzada y tecnología de compuestos

Nuestros defensas se producen utilizando técnicas avanzadas de moldeo y vulcanización que garantizan una unión perfecta y una densidad uniforme. Los compuestos de goma están diseñados para mantener una alta resiliencia y resistencia mecánica incluso bajo ciclos de deformación continuos, lo que garantiza un rendimiento a largo plazo y una degradación mínima.

Diseño personalizado e integración de sistemas

Cada sistema de defensa está diseñado de acuerdo con los parámetros operativos del cliente: tamaño de la embarcación, rango de mareas y velocidad de atraque. El equipo de ingeniería de Hongruntong utiliza el análisis de elementos finitos (FEA) para simular la absorción de energía y optimizar la geometría del defensa, garantizando la máxima seguridad y rentabilidad. Paneles frontales, almohadillas y marcos de montaje personalizados opcionales están disponibles para la integración llave en mano.

Servicio integral y soporte técnico global

Hongruntong proporciona soporte completo para el proyecto, desde la consulta de diseño y la instalación in situ hasta el mantenimiento y la inspección a largo plazo. Con centros de servicio en Asia, Oriente Medio y Europa, nuestra red logística garantiza la entrega rápida y el soporte al cliente receptivo para proyectos portuarios y marinos internacionales.

Preguntas frecuentes

1. ¿Cuánto tiempo suele durar un defensa de goma de arco?

Dependiendo del uso y la exposición ambiental, los defensas de goma de arco generalmente duran entre 10 y 20 años con un mantenimiento adecuado.

2. ¿Se pueden personalizar los defensas de arco para diseños de atraque específicos?

Sí, los defensas se pueden fabricar en varias alturas, longitudes y grados de dureza para adaptarse a condiciones estructurales o de marea únicas.

3. ¿Son necesarias almohadillas frontales adicionales?

Para el contacto de alta fricción o embarcaciones con casco de acero, se recomiendan almohadillas frontales de UHMW-PE o goma para reducir la abrasión y prolongar la vida útil.

4. ¿Cómo se deben mantener los defensas?

Inspeccione visualmente cada 6 a 12 meses para detectar desgaste superficial o aflojamiento de los pernos. Limpie regularmente y reemplace las almohadillas desgastadas si están equipadas.

5. ¿Hongruntong proporciona soporte de instalación?

Sí, ofrecemos dibujos de ingeniería completos, hardware de montaje y supervisión in situ para garantizar la correcta instalación y el rendimiento.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!