Defensa de Goma Marina, Goma de Alta Resistencia, Absorción Superior de Impactos, Fiabilidad Probada

Descripción

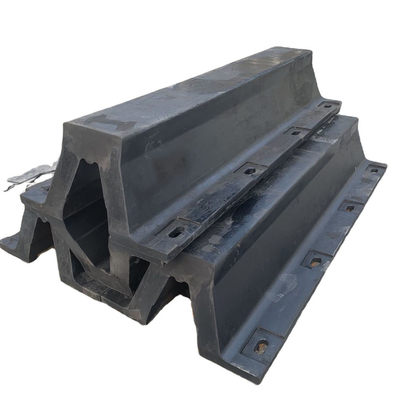

La defensa de goma para muelles tipo V está diseñada para proporcionar una protección superior a los buques durante el atraque, preservando la infraestructura del muelle. Fabricada con goma sintética de alta calidad, ofrece una excelente elasticidad, resistencia al desgaste y protección contra la corrosión en condiciones marinas adversas. Su geometría en forma de V asegura una distribución efectiva de la energía del impacto, reduciendo el estrés localizado tanto en los buques como en los muelles.

Estudio de Caso

En el puerto de Hamburgo, se instalaron defensas tipo V a lo largo de una terminal de cruceros. En un año, los operadores de la terminal observaron una disminución significativa en los pequeños arañazos en el casco y los daños en la pared del muelle, incluso con el atraque frecuente de grandes cruceros que superaban las 100.000 GT. El diseño de la defensa proporcionó una protección fiable en operaciones de alto tráfico, garantizando la seguridad y la eficiencia operativa.

Especificaciones

| Lugar de Origen |

China |

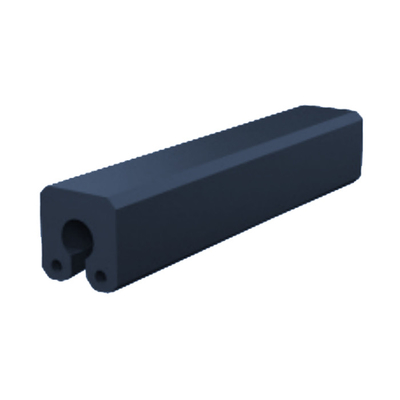

| Nombre del Producto |

Defensa de Goma para Muelles |

| Tipo |

Tipo en Forma de D |

| Servicio de Procesamiento |

Moldeado por Compresión |

| Color |

Negro (Más Colores Opcionales) |

| Material |

NR Suave |

| Rendimiento |

Excelente Propiedad Química y Física |

| Logotipo |

Solicitud del Cliente |

| Aplicación |

Puerto, Muelle, Barco |

| Tipo |

Especificaciones |

| H |

B |

L |

Agujeros |

Q |

C |

h |

El desarrollo continuo de productos asegura que nuestras defensas cumplan con las demandas cambiantes de los puertos. Las pruebas de rendimiento incluyen evaluaciones de resistencia a la tracción, compresión y ambientales. |

d |

| D150x150x1000 |

150 |

150 |

1000 |

3 |

350 |

150 |

25 |

40 |

24 |

| D200x200x1000 |

200 |

200 |

1000 |

3 |

353 |

150 |

35 |

55 |

30 |

| D200x200x3000 |

200 |

200 |

3000 |

8 |

400 |

100 |

35 |

55 |

30 |

| D250x250x1000 |

250 |

250 |

1000 |

3 |

350 |

150 |

35 |

60 |

30 |

| D250x250x3000 |

250 |

250 |

3000 |

8 |

400 |

100 |

35 |

60 |

30 |

| D300x300x1000 |

300 |

300 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x300x3000 |

300 |

300 |

3000 |

8 |

400 |

100 |

40 |

65 |

32 |

| D300x360x1000 |

300 |

360 |

1000 |

3 |

350 |

150 |

40 |

65 |

32 |

| D300x360x3000 |

300 |

360 |

3000 |

8 |

400 |

100 |

40 |

65 |

40 |

| D400x400x1000 |

400 |

400 |

1000 |

3 |

400 |

150 |

55 |

80 |

32 |

| D400x400x3000 |

400 |

400 |

3000 |

8 |

400 |

100 |

55 |

80 |

40 |

| D500x500x1000 |

500 |

500 |

1000 |

3 |

350 |

150 |

90 |

97 |

45 |

| D500x500x3000 |

500 |

500 |

3000 |

8 |

400 |

100 |

90 |

97 |

45 |

| DATOS TÉCNICOS |

| PROPIEDADES |

NORMA DE ENSAYO |

VALORES |

| Compuesto |

- |

NR / SBR |

| Densidad (Gravedad Específica) |

DIN 53505 |

1200 kg/m3 |

| Resistencia a la Tracción |

DIN 53504 |

≥16 MPa |

| Elongación a la Rotura |

DIN 53504 |

≥350% |

| Resistencia al Desgarro (23°C) |

DIN 53507 |

≥80 N/cm |

| Resistencia a la Abrasión |

DIN 53516 |

≤100mm3 |

| Deformación por Compresión (24 horas @ 70°C) |

DIN 53517 |

≤40% |

| Resistencia al Ozono (ppm 20% 72 horas @ 40°C) |

ISO 143/1 |

No se Ven Grietas a Simple Vista |

| Cambio en la Dureza |

DIN 53504 |

≤5° |

| Cambio en la Resistencia a la Tracción |

DIN 53504 |

≥80% |

| Cambio en la Elongación a la Rotura |

DIN 53504 |

≥80% |

| Temperatura Mínima |

- |

-30°C |

| Temperatura Máxima |

- |

+70°C |

Características

Absorción de Energía Optimizada

La forma en V permite que la defensa se comprima y disipe la energía de manera uniforme en toda la superficie de contacto. Las pruebas de simulación indican una mejora del 40–50% en la reducción de la fuerza de impacto en comparación con las defensas tradicionales.

Material de Goma Duradero

Nuestra goma sintética de primera calidad resiste la abrasión, la radiación UV y la corrosión por agua salada. Las pruebas de laboratorio confirman que el material conserva más del 90% de su elasticidad después de una exposición prolongada al aire libre.

Fácil Instalación y Mantenimiento

El diseño modular permite una instalación vertical u horizontal flexible. Las secciones se pueden reemplazar individualmente sin desmontar todo el sistema de defensa, lo que reduce el tiempo de inactividad y los costos de mantenimiento.

Rentable y Ecológico

La larga vida útil reduce la frecuencia de reemplazo y los costos operativos. La goma segura para el medio ambiente garantiza el cumplimiento de las normas ecológicas marinas.

Aplicaciones

Terminales de Cruceros

Protege tanto a los buques como a las estructuras del muelle de los impactos repetidos de atraque.

Puertos de Contenedores

Absorbe la energía cinética de los buques portacontenedores pesados, reduciendo el estrés en las paredes del muelle.

Puertos de Carga Industrial

Adecuado para graneleros, petroleros y buques de carga general, lo que garantiza un atraque seguro en los puertos industriales.

¿Por Qué Elegir Hongruntong Marine?

I+D Innovadora

El desarrollo continuo de productos asegura que nuestras defensas cumplan con las demandas cambiantes de los puertos. Las pruebas de rendimiento incluyen evaluaciones de resistencia a la tracción, compresión y ambientales.

Control Estricto de Fabricación

El moldeo de precisión y el control de calidad certificado ISO 9001 garantizan una fiabilidad constante del producto para todos los lotes de defensas.

Validación del Mercado Global

Las instalaciones exitosas en Hamburgo, Rotterdam y Singapur demuestran el rendimiento del producto en diversas condiciones marítimas.

Soporte Integral al Cliente

La orientación técnica, la capacitación en mantenimiento y los servicios postventa de respuesta rápida garantizan un funcionamiento sin problemas y una asociación a largo plazo.

Preguntas Frecuentes

1. ¿Se pueden utilizar estas defensas para mega cruceros?

Sí, son adecuadas para buques que superan las 100.000 GT.

2. ¿Qué mantenimiento se requiere?

La inspección y limpieza periódicas son suficientes para mantener un rendimiento óptimo.

3. ¿Hay tamaños personalizados disponibles?

Sí, podemos producir defensas para que coincidan con los requisitos específicos del puerto o del buque.

4. ¿Qué tan resistentes son a los productos químicos?

El material de goma es resistente al agua salada y a los contaminantes industriales típicos, ideal para puertos químicos e industriales.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!