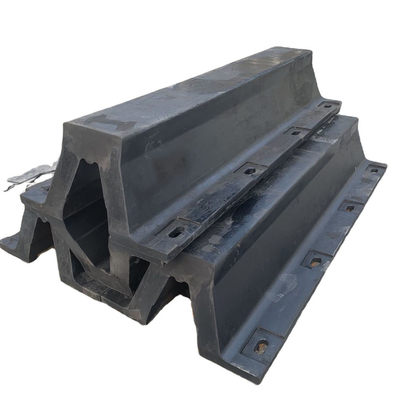

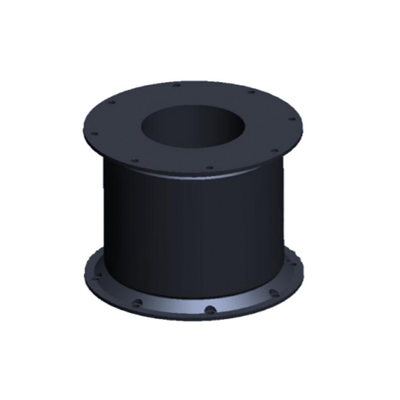

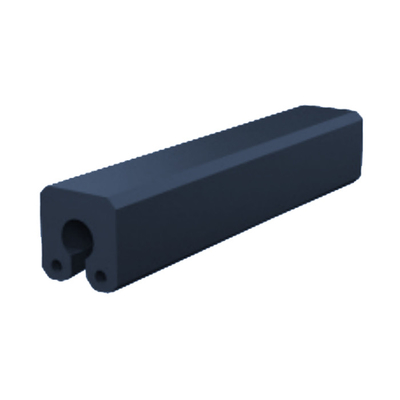

Defensas de espuma marina: resistentes a impactos, duraderas, fáciles de instalar y manejar

Descripción

En las operaciones en alta mar, las defensas flotantes de espuma son cruciales para proteger los buques de suministro y las plataformas. Su resistencia al agua de mar, los rayos UV y los fuertes impactos las hace ideales para condiciones marinas extremas.

(Caso: Una plataforma de perforación en alta mar en África Occidental utilizó defensas flotantes de espuma para el atraque de los barcos de suministro. Las defensas absorbieron las fuertes fuerzas de impacto de los buques que transportaban equipos y suministros pesados. Incluso con un uso continuo, las defensas mantuvieron su forma y rendimiento, lo que demostró ser rentable y mejoró la seguridad para las operaciones en alta mar. )

Especificaciones

|

Diámetro x Longitud

|

Absorción de energía al 60% de compresión

|

Fuerza de reacción al 60% de compresión

|

Peso aprox.

|

|

(mm)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 x 1000

|

3.8

|

54

|

11

|

|

500 x 1000

|

10.6

|

91

|

41

|

|

600 x 1000

|

15.3

|

109

|

49

|

|

600 x 1000

|

18.3

|

131

|

55

|

|

700 x 1500

|

31

|

191

|

85

|

|

750 x 1500

|

36

|

204

|

89

|

|

900 x 1800

|

62

|

294

|

140

|

|

1000 x 1500

|

64

|

272

|

125

|

|

1000 x 2000

|

85

|

363

|

170

|

|

1200 x 2000

|

122

|

436

|

275

|

|

1200 x 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 x 2500

|

165

|

567

|

410

|

|

1500 x 3000

|

286

|

817

|

570

|

|

1500 x 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 x 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 x 4000

|

1059

|

1815

|

1865

|

|

2500 x 5000

|

1324

|

2269

|

2500

|

|

2500 x 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 x 5000

|

1925

|

2750

|

3200

|

|

3000 x 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 x 8000

|

4522

|

5809

|

8700

|

|

4200 x 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

Características

Apariencia personalizable

La superficie de la defensa se puede personalizar con diferentes colores, logotipos o marcas de identificación, lo que permite una fácil gestión de la marca y operativa.

Versatilidad en todas las aplicaciones

Adecuadas para puertos, bases navales, plataformas en alta mar, transferencias STS (de barco a barco) y terminales Ro-Ro, las defensas de espuma brindan protección multipropósito.

Fácil instalación

El diseño ligero y la configuración sencilla permiten una instalación rápida sin equipos especializados, lo que reduce los costos de mano de obra y el tiempo de inactividad.

Seguras para el medio ambiente

Las defensas de espuma están diseñadas con materiales no tóxicos y no representan riesgos de contaminación para el medio ambiente marino, a diferencia de algunos sistemas de defensa más antiguos.

Aplicaciones

Apoyo a la construcción en alta mar

En los proyectos de petróleo y gas en alta mar, las bolsas de elevación neumáticas ayudan a posicionar estructuras submarinas pesadas, tuberías y equipos durante las operaciones de instalación y mantenimiento.

Instalación y reparación de tuberías

Las bolsas de elevación neumáticas submarinas proporcionan control de flotabilidad durante la colocación y reparación de tuberías submarinas, lo que ayuda a posicionar y soportar secciones durante la soldadura y la conexión.

Demolición submarina

Los equipos de demolición utilizan bolsas de elevación neumáticas para levantar y retirar de forma segura estructuras submarinas, componentes de puentes o restos después de explosiones controladas o desmantelamiento.

Ventajas

Estricto control de calidad

Cada defensa se somete a rigurosas pruebas de resistencia, absorción de energía y durabilidad, lo que garantiza un rendimiento constante.

Cumplimiento de las normas certificadas

Nuestros productos cumplen con las normas internacionales como ISO, PIANC y las directrices de OCIMF para defensas marinas.

Soluciones personalizadas

Proporcionamos tamaños, colores y diseños de defensas a medida de acuerdo con los requisitos del cliente y las condiciones del proyecto.

Materiales duraderos

Utilizamos espuma de celda cerrada de primera calidad y elastómeros de poliuretano de alta calidad para maximizar la vida útil y la resistencia a entornos hostiles.

Preguntas frecuentes

1. ¿Son respetuosas con el medio ambiente?

Sí. Los materiales no son tóxicos y no contaminan el medio ambiente marino.

2. ¿Qué industrias utilizan comúnmente defensas de espuma?

Puertos comerciales, terminales de petróleo y gas, plataformas en alta mar, fuerzas navales y terminales de ferry/Ro-Ro.

3. ¿Cómo se envían?

Las defensas se embalan con envoltorios protectores y se envían de forma segura en contenedores o en bastidores planos, según el tamaño.

4. ¿Pueden reemplazar las defensas neumáticas existentes?

Sí. Las defensas de espuma se utilizan a menudo como reemplazo a largo plazo de las defensas neumáticas debido a su durabilidad y bajo mantenimiento.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!